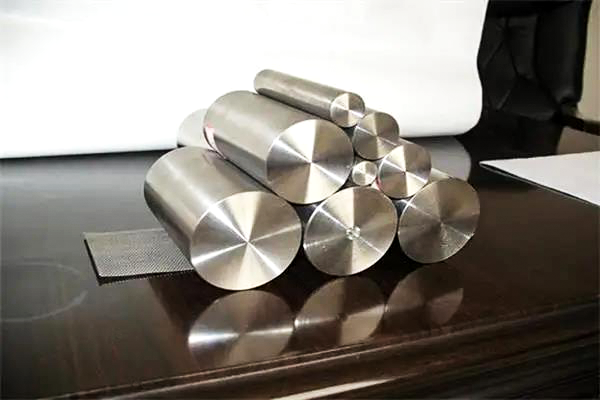

Nickel base alloy is a kind of alloy with nickel as the matrix (the content is generally more than 50%), which can maintain high strength, good oxidation resistance and gas corrosion resistance under high temperature in the range of 650~1000 ℃.

Wear-Aesistant Alloy

The main alloy elements are chromium, molybdenum, tungsten, and a small amount of niobium, tantalum and indium.

The main alloy elements are chromium, tungsten, molybdenum, cobalt, aluminum, titanium, boron, zirconium, etc. Among them, Cr, Ai and other elements mainly play the role of oxidation resistance, while other elements have the role of solid solution strengthening, precipitation strengthening and grain boundary strengthening.

Application Area:

1. Oceans: marine structures of marine environment, seawater desalination, mariculture, seawater heat exchange, etc.

2. Environmental protection: flue gas desulfurization device for thermal power generation, wastewater treatment, etc.

3. Energy field: atomic power generation, comprehensive utilization of coal, tidal power generation, etc.

4. Petrochemical industry: oil refining, chemical equipment, etc.

5. Food field: salt making, soy sauce brewing, etc.

Tel:+86-21-67890007

Tel:+86-21-67890007

E-mail:inquiry@ninesteel-cs.com

E-mail:inquiry@ninesteel-cs.com

Inquiry Now

Inquiry Now