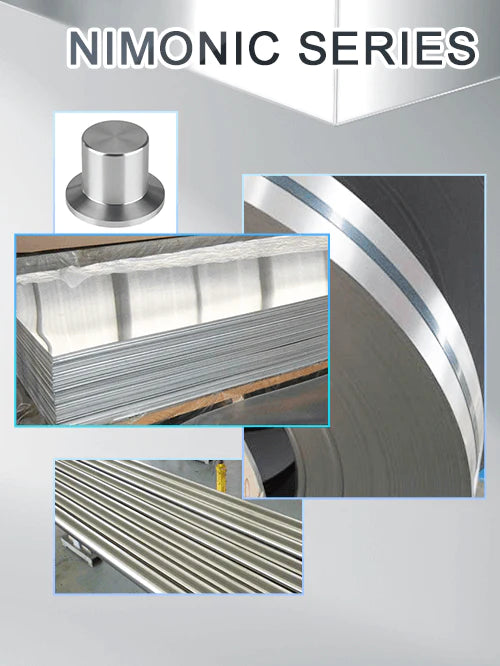

Nimonic 263

The primary element in Nimonic 263 is nickel, which makes up 73% of the alloy by weight. The remainder of the alloy is composed of chromium (20%), cobalt (5%), and molybdenum (2%). These elements work together to create an incredibly durable and heat-resistant material. Thanks to its low coefficient of thermal expansion, it can withstand extreme temperature fluctuations without cracking or deforming. This makes it ideal for use in high-performance engines subjected to rapid temperature changes over short periods

Applications:

Nimonic Alloy 263 is mainly used in gas turbine hot section components.

Get a free Quote

inquiry-carbon@ninesteel-cs.com

inquiry-ru@ninesteel-cs.com

Get a free Quote

Tel:+86-21-67890007

Tel:+86-21-67890007

E-mail:inquiry@ninesteel-cs.com

E-mail:inquiry@ninesteel-cs.com

Inquiry Now

Inquiry Now