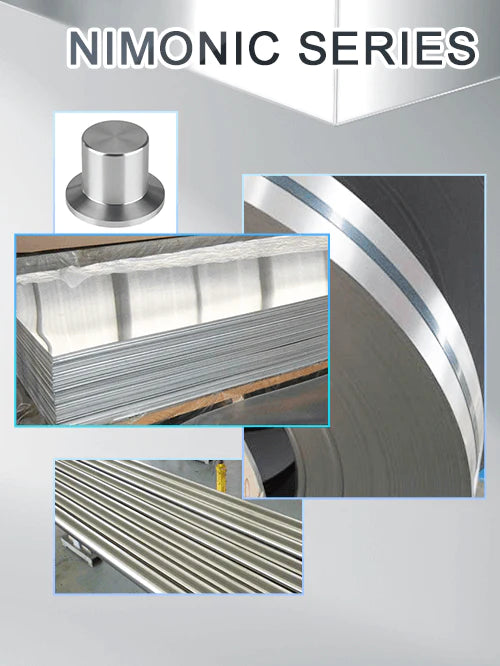

Nimonic 90

Nimonic® 90 is also known as Superimphy 90, Pyromet 90, and Udimet 90.

Applications:

Traditionally used in the production of gas turbine blades and hot working tools, Nimonic 90 is also popular in the motorsport and automotive sector.

The alloy is useful in applications where high mechanical stress and high temperature is a consideration, including specific engine applications, high-temperature springs and high-performance engine valves. The product is also a preferred choice for extreme high boost pressure turbocharged applications.

Get a free Quote

Get a free Quote

Tel:+86-21-67890007

Tel:+86-21-67890007

E-mail:inquiry@ninesteel-cs.com

E-mail:inquiry@ninesteel-cs.com

Inquiry Now

Inquiry Now